Farm Trader

IT's ISOBUS baby!

You can spot a SAM a mile away. The distinctive bright yellow and green machinery has been popping up all over New Zealand countryside across three generations.

SAM is well-known for being at the forefront of fertiliser spreading in New Zealand and is now leading the charge with its next evolution of computer-controlled gear.

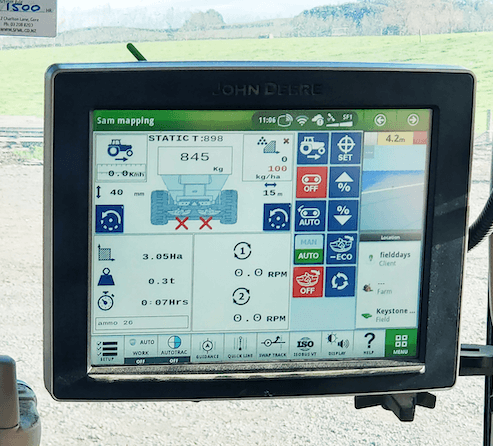

The Topcon SAM Spreader stands out because it's ISOBUS. The spreader simply plugs into an compliant tractor. The display then shows up on the in-cab screen. This saves having to purchase and run an additional screen and means owners and operators can swap easily between tractors. It gives precise control for spreading all types of fertilisers, manure, and animal waste, proving popular with contractors where accuracy and proof of placement are a must.

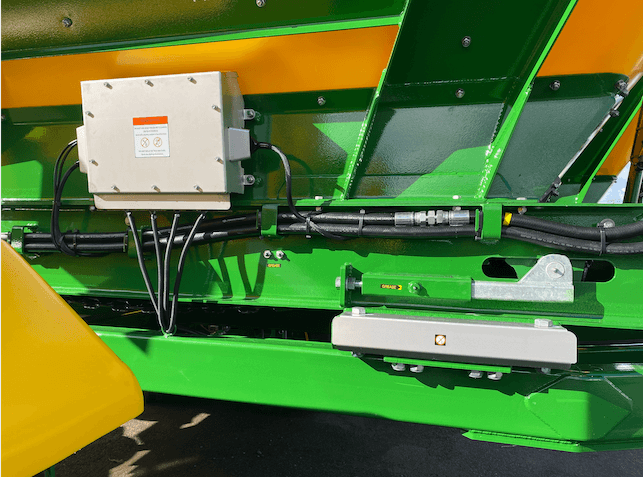

Design engineer Toby Stone says, "This added automation is exciting; it means the best in traceability and accuracy, giving our customers peace of mind. "The floor is hydraulically controlled rather than manually driven off the wheel. This means the correct application rate is applied regardless of changes in forward speed or in product density. Simply enter key details such as tractor centres, product density, and the rate to apply - and you are away."

Proof of placement is integrated into the system without relying on third-party reporting. Owners are paying once for their gear and not again every month thereafter for various subscriptions.

Any SAM Spreader can be upgraded to Topcon control at the time of build. Elements are customisable to suit individual needs - screen, GPS, LOAD CELLS, ETC. By adding load cells, the fully integrated system will also allow dynamic rate control. This uses the weight of the product to constantly check the spread rate as you go. It's the only way to get true accuracy.

ISOBUS tech allows for the use of all of the tractor's high-tech features such as autosteer, headland turning, border control, light bar, the ability to save product settings, sectional control, variable rate control, fleet management, and proof of placement reporting (heat maps).

The full system can be purchased through SAM for those with a non-ISOBUS tractor. An electric back door is a new optional extra. The back door electronically moves to the appropriate height based on inputs. Topcon tech was chosen by SAM for reliability. The system has been proven through decades of R&D and decades of international experience.

"The best high-end tech on New Zealand's favourite spreader was a natural fit," says SAM business manager, Tim Ellingham.

The SAM spreader range has three tiers: simple manual drives, the new e-Spreaders for added accuracy, and the high-end Topcon spreaders.

- e-Wagon launch

- New pricing app for SAM dealers

- Accurate & connected

- Protect your gear with the SAM coating…

- SAM Footprint

- Local manufacturer builds spreader for orchards

- Dairy farmer moves to big league

- e-Spreader - e for easy!

- Sharp design - reinvented

- Celebrating 50 years at the Fieldays

- New digs for SAM!

- New kids on the block

- Have your say on SAM’s next donation

- Steel decks on every SAM Trailer

- Stainless side-feeds a breeze to maintain

- SAM continues to make its mark

- SAM's the man

- Corrosion resistant paintwork

- More stainless. Less worries.

- Accuracy and testing for SAM Spreaders

- Kiwi favourite marks 75 years in business

- SAM Computer Control

- Meet the NEW SAM Orchard Spreader

- Made in NZ...SAM Machinery

- Topcon Tips

- Shout out to SAM - 75 Yrs!

- Review: SAM Orchard Spreader

- It's Isobus baby!

- Proudly NZ-Made

- Proven to last the distance

- Easy-to-use SAM orchard spreader gives BOP contractors…

- SAM Machinery welcomes new head

- What's the go at Fieldays