- e-Wagon launch

- New pricing app for SAM dealers

- Accurate & connected

- Protect your gear with the SAM coating…

- SAM Footprint

- Local manufacturer builds spreader for orchards

- Dairy farmer moves to big league

- e-Spreader - e for easy!

- Sharp design - reinvented

- Celebrating 50 years at the Fieldays

- New digs for SAM!

- New kids on the block

- Have your say on SAM’s next donation

- Steel decks on every SAM Trailer

- Stainless side-feeds a breeze to maintain

- SAM continues to make its mark

- SAM's the man

- Corrosion resistant paintwork

- More stainless. Less worries.

- Accuracy and testing for SAM Spreaders

- Kiwi favourite marks 75 years in business

- SAM Computer Control

- Meet the NEW SAM Orchard Spreader

- Made in NZ...SAM Machinery

- Topcon Tips

- Shout out to SAM - 75 Yrs!

- Review: SAM Orchard Spreader

- It's Isobus baby!

- Proudly NZ-Made

- Proven to last the distance

- Easy-to-use SAM orchard spreader gives BOP contractors…

- SAM Machinery welcomes new head

- What's the go at Fieldays

RURAL CONTRACTOR

Accurate & connected

Automate your reporting this season and save.

Was $80/month. For a limited time only $64/month.

Connect your tractor or spreader to MyBallance, Hawkeye or Precision Farming this winter and get 15 months of access for the price of 12. That’s the first 3 months absolutely FREE!

Streamline your compliance reporting and farm record-keeping with automated connectivity, saving you both time and hassle, and keeping more money in your pocket.

Visit the SAM site at Fieldays to learn more. Precision Farming will be doing a demo at 10am & 1.45am each day.

Or get in touch with Precision Farming directly to chat about it.

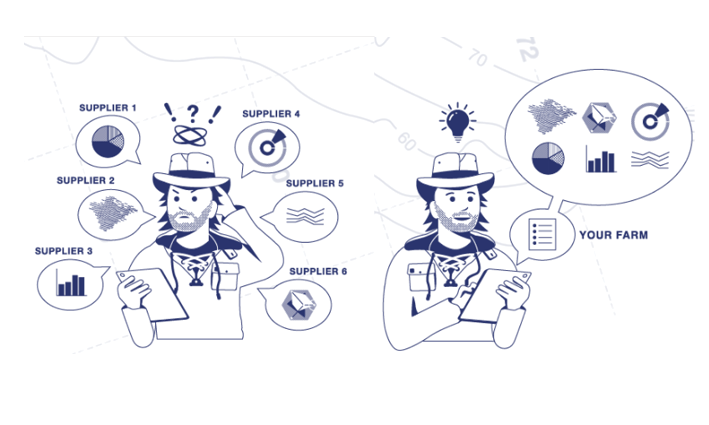

Do you want to connect your spreader with Hawkeye or MyBallance? If so, SAM Machinery has you covered. If you have a SAM Topcon spreader you can seamlessly integrate your business with your fertiliser cooperative via Precision Farming.

This set-up combines ISOBUS compatibility and common-sense. You can easily share your data so it goes where it needs to be without manual re-entry. It allows you to order, dispatch, report and apply a farm’s inputs using a simple interface. It even lets you view work in real time for fleet management.

You can reduce manual steps and get accurate documentation with minimal effort while saving thousands on third party gear and extra subscriptions.

How does it work?

1. You place an order for fertiliser or chemicals on the farm’s digital map in HawkEye, MyBallance or Precision Farming.

2. The Precision Farming dispatch platform receives the order and at the push of a button is sent into TAP and the Topcon console in the tractor.

3. Proof of application then returns to Precision Farming and, if connected, to HawkeEye or My Balance for simple record keeping and automated compliance reporting.

SAM’s Topcon spreaders are the top end of its range. The other two tiers in the range are simple manual drives and e-Spreaders.

The same clever design and build quality is assured across the SAM range. They include spreaders with single or tandem axles and carrying capacities of 4, 5 and 6 tonnes. Combo spreaders can handle 5-9 tonnes of processed fertiliser or organic material, and SAM now offers a new orchard spreader.

TOPCON SPREADERS

This is the ultimate in control with accuracy as high as 99 percent of the target rate. SAM Topcon spreaders are popular with contractors and large scale farmers.

With Topcon’s well-proven guidance and load cells plus ISOBUS they deliver precision and convenience. Now, for a small connection fee with Precision Farming, these spreaders can link directly with your fert suppliers.

The Topcon computer controls the floor speed hydraulically from a screen in the tractor cab. It can use the weight of the product to constantly check the spread rate on the move, so you can spread more accurately and provide traceability.

You can plug your SAM Topcon spreader directly into an ISOBUS tractor. Proof of placement is integrated into the system so you don’t have to rely on third party reporting. Extra features include dynamic rate control, mapping, and variable rate spreading.

ISOBUS sectional control for headlands or cross over areas means no areas will receive a double application.

E-SPREADERS

The SAM e-Spreader is a simple, accurate computer-controlled spreader. It is straight-forward to learn and use, and it is great if you have a third party GPS system but don’t have an ISOBUS tractor.

With added accuracy you save money on inputs. Simply set your rate from the screen in the cab. It also has integrated load cells, electric back door, unloading function and border control.

SAM e-Spreaders are easy to calibrate and come with load cells. Load cells are the only way to get true accuracy because they weigh the fertiliser as you go and apply the correct application rate regardless of changes in forward speed.

e-Spreaders integrate easily with third party GPS systems. You can see what you have covered and how much you have actually applied, so proof of placement is easy. If you already use a third party tracking system like Tabula or Trimble you don’t have to reinvent the wheel.

The SAM controller screen in the cab features reliable German hardware and clever Kiwi software. Setting your spread rate is simple – just key in your spread rate, your product density and spread width.

MANUAL DRIVE

SAM Manual drive spreaders keep things very simple, which is great if you have different operators with different skill levels.

The floor mat is driven off the forward speed of the wheel. You simply wind the back door height to the rate you want to be spreading. The label on the back door indicates different products and application rates.

Load cells can be added at the time of build. They connect to a simple app on your Android phone, which shows you the actual weight in the bin at any point in time.