2.5 cubic metres

Simple and versatile.

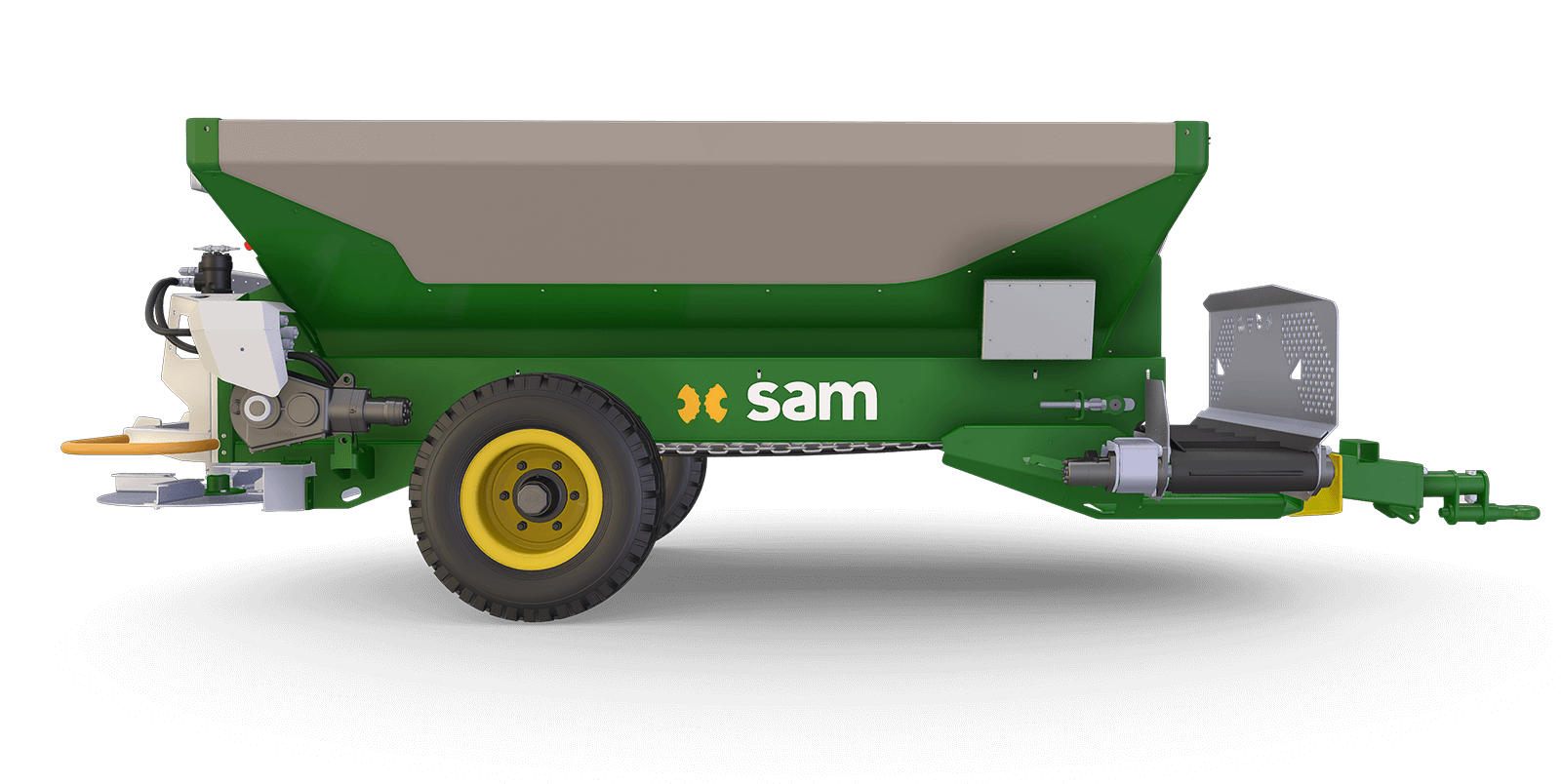

With the same practical design and easy to use operation that all SAM’s are known for, SAM Orchard Spreaders are made to meet the needs of modern orchards. They have a lower profile and narrower width, and provide great versatility around what you are able to spread.

Designed primarily for spreading organic matter such as compost, green matter, vermicast and mulch. This machine will also spread processed fertiliser like superphosphate, lime and urea with absolutely no change-over time!

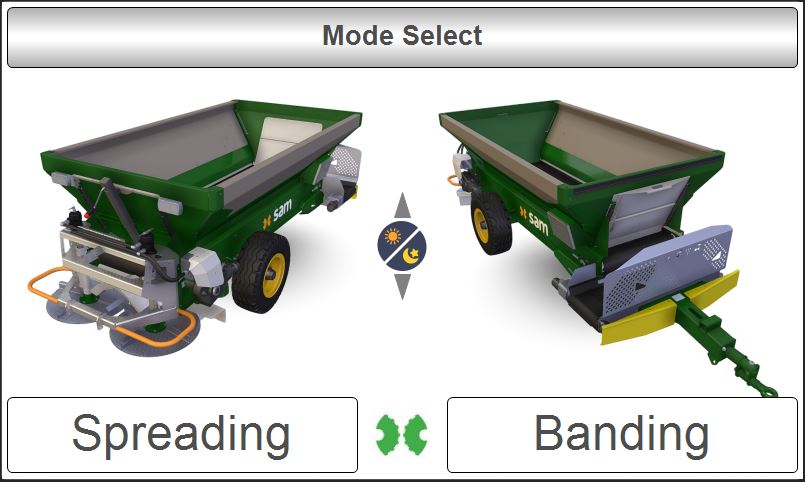

SAM Computer control

This Orchard Spreader includes a computer controlled hydraulic floor. The SAM controller allows you to choose between spreading or banding at the touch of a button. Rates are input from your tractor and you are away.

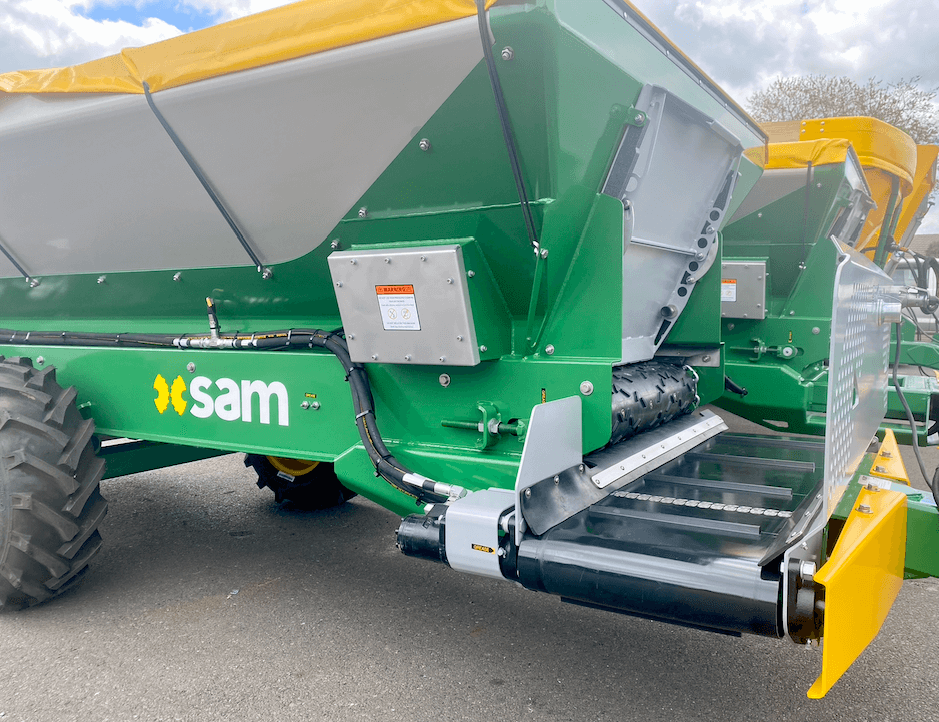

Banding compost, green matter and mulch using the side conveyor

The floor mat moves toward the front of the machine, moving material onto the side banding conveyor. This creates a precise banding or piling pattern in full view of the operator. Direction of the banding can also be switched to the opposite side, handy for rut filling (optional extra).

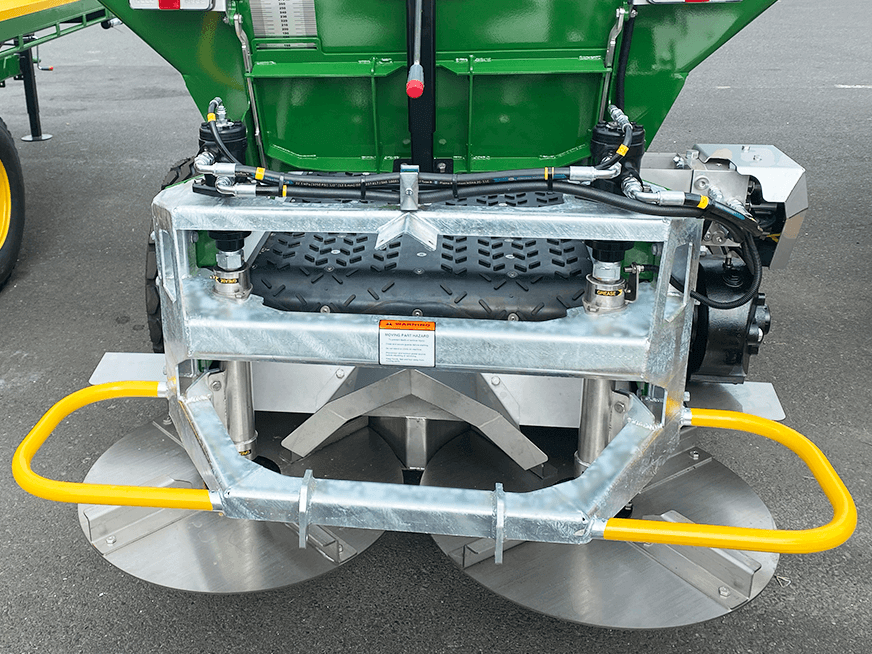

Spreading organic material and processed fertilisers using spinners

For a spread pattern behind the machine, the floor mat moves backwards toward the spinners. For different planting centres, spread widths can be changed by setting the speed of the spinners from the controller.

30-60 l/min required from your tractor.

Smart Features

-

Watch the SAM Orchard Spreader in action

This quick video gives you a preview of the SAM Orchard Spreader in action. Check out how well the bin empties!

-

Everything from lime to compost to mulch

Spread the likes of super, lime, urea, sand & poultry/pig manure out back and band/pile compost, vermicast, green matter & mulch out front. Very very versatile.

-

Side conveyor for banding. 2 for 1!

This compact conveyor spreads material in a line to the right hand side of the Orchard Spreader. Great for banding where you need to apply product in a line or a pile. Designed to be in full view of the operator.

-

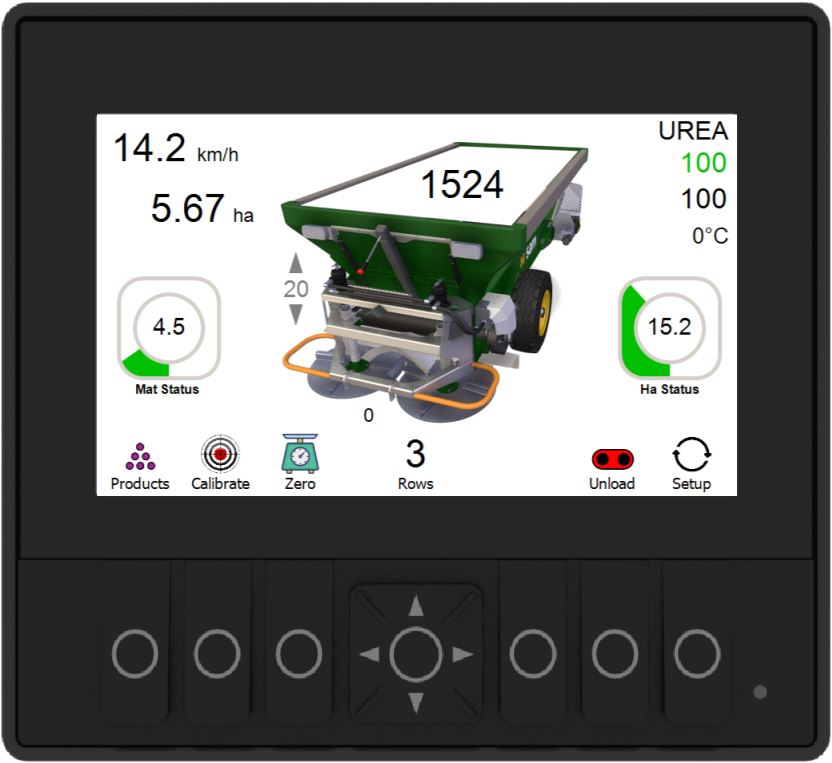

SAM computer controller

Quality German hardware coupled with smart Kiwi software. Turning on/off and controlling the functions of the spreader is simple. Just use the intuitive controller in your tractor. The screen is suitable for open cabs due to its high water rating (IP67).

-

Instant control switch

Simply flick the switch for instant starting and stopping of application. No more anticipating when your product is going to come out. There is also a piling timer set from your controller for even bursts of application.

-

Even does mulch!

There are three positions for the front door depending on what you are wanting to spread 1 Closed (for spreading at rear), 2 Half open (for banding at a volumetric rate) and 3 Completely removed (mulch, woodchip, bark, compost or green waste).

-

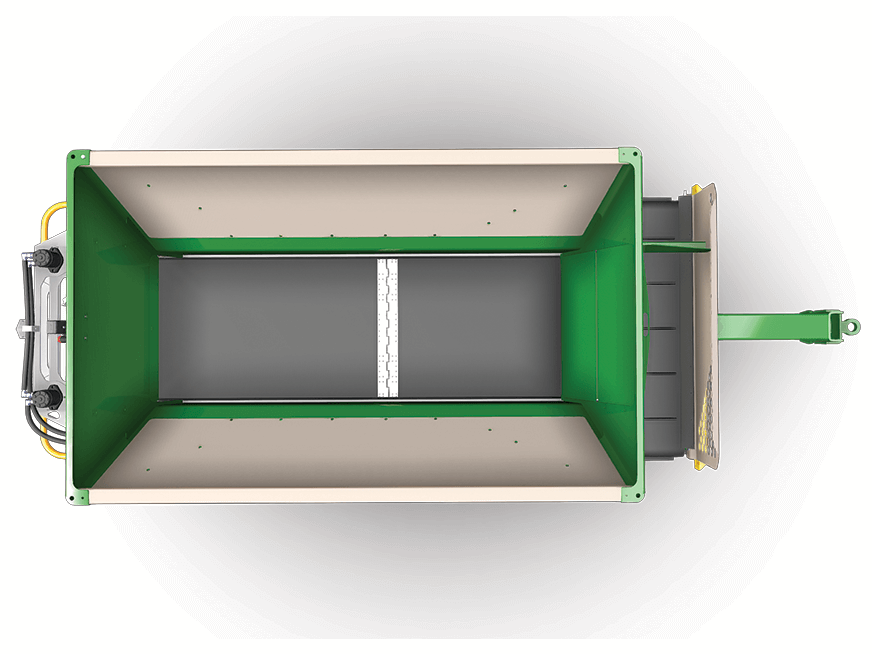

Strong stainless panels

Stainless bins are extremely corrosion resistant. With every component designed for reliability - your repairs and maintenance on these machines will be very low.

-

More stainless for longevity

Majority stainless at the rear of the machine, extends longevity of gear where you need it most. Stainless discs are run via enclosed stainless spinner tubes and two well proven speed adjustable hydraulic motors. Reliable as.

-

Review

Watch this Farm Trader video. Or read their full review in our News section. All machines come standard with an 800mm wide floor-belt, control screen, safety nudge bars, back spinner assembly and fixed front conveyor.

-

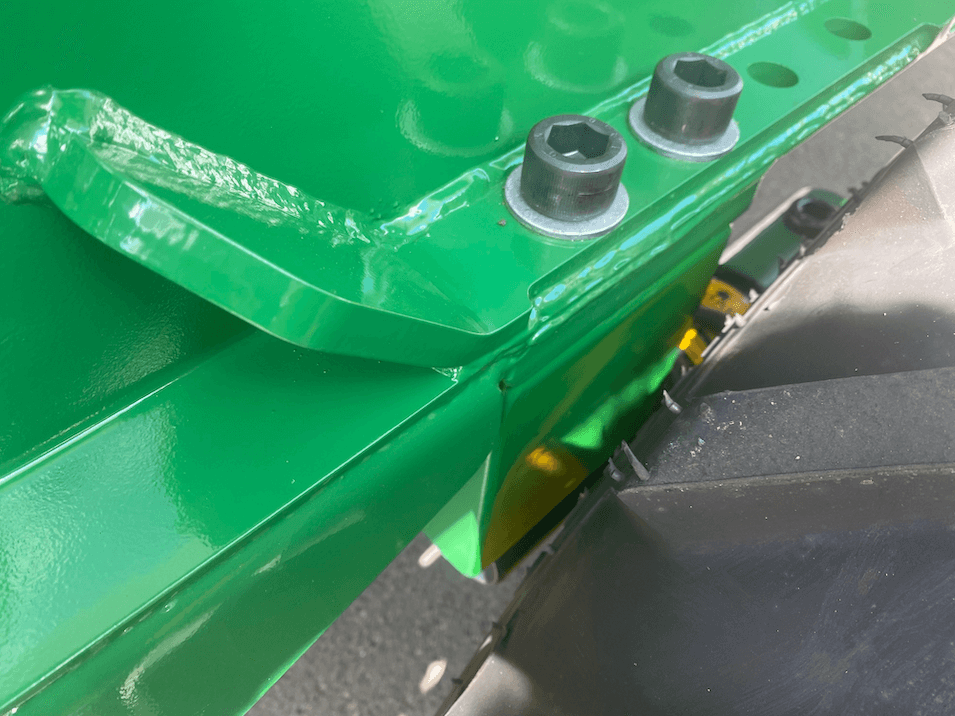

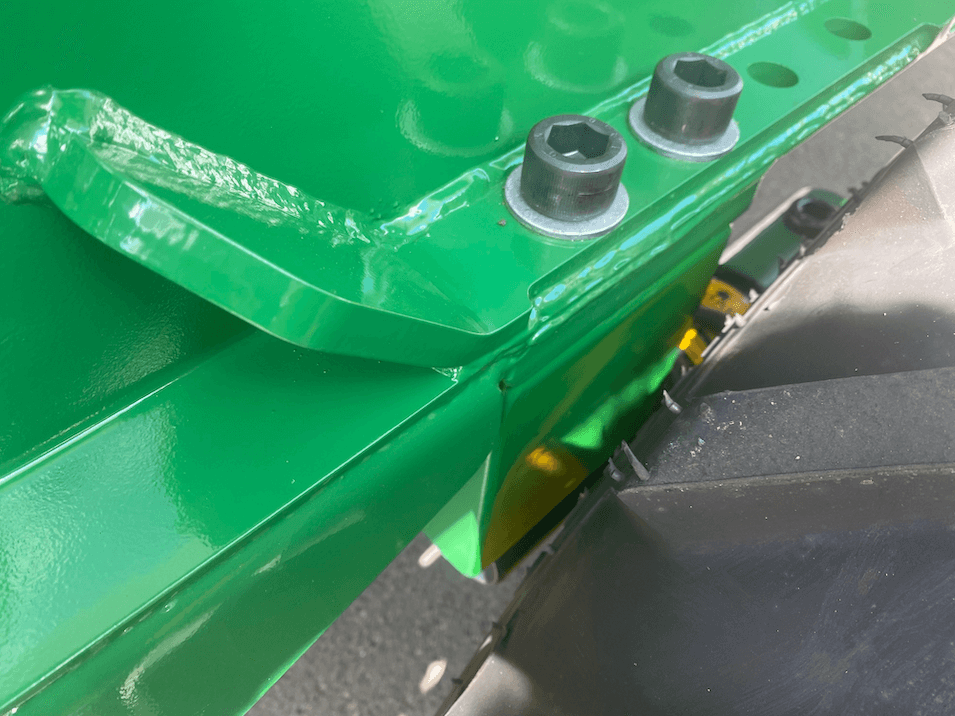

Industry leading coating protection system

All chassis's on SAM Orchard Spreaders have seen a new evolution of painting procedure. This is for extra corrosion protection. Firstly a blast then a thermal-arc spray followed by the SAM coating difference. It is mega tough stuff!

-

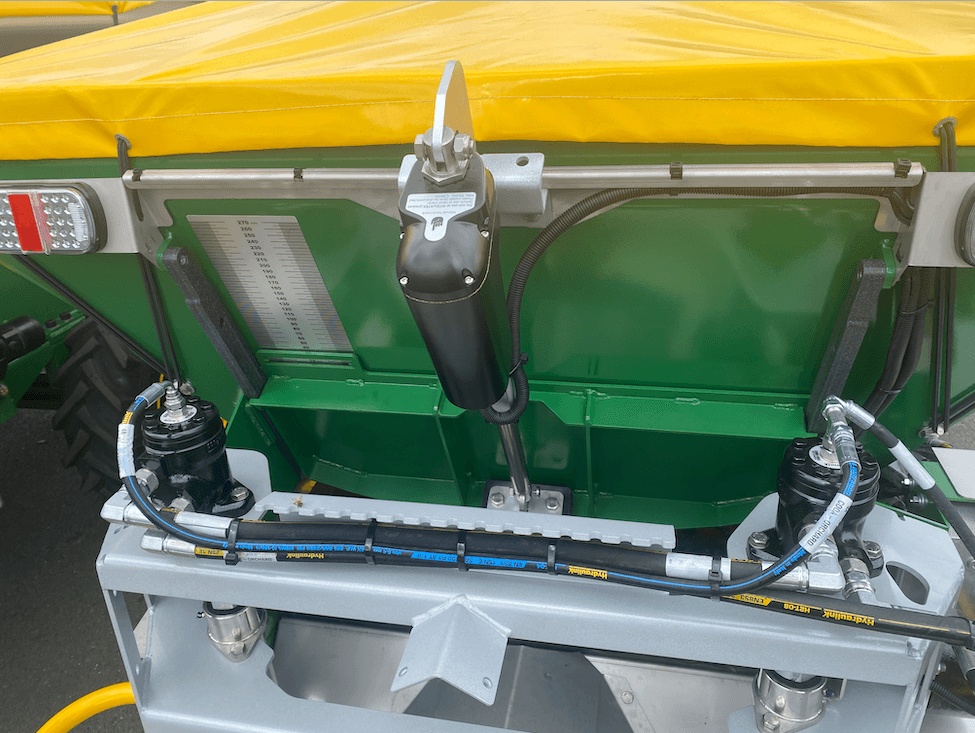

Tophat extensions (optional)

This spreader now has the largest bin capacity on the market. If you wish to add to that, there are two sizes available. The largest top hat increases your capacity by 2 cubic metres (shown here). The smaller tophat increases your capacity by 1 cubic metre. These have been popular for our NZ wine growers.

-

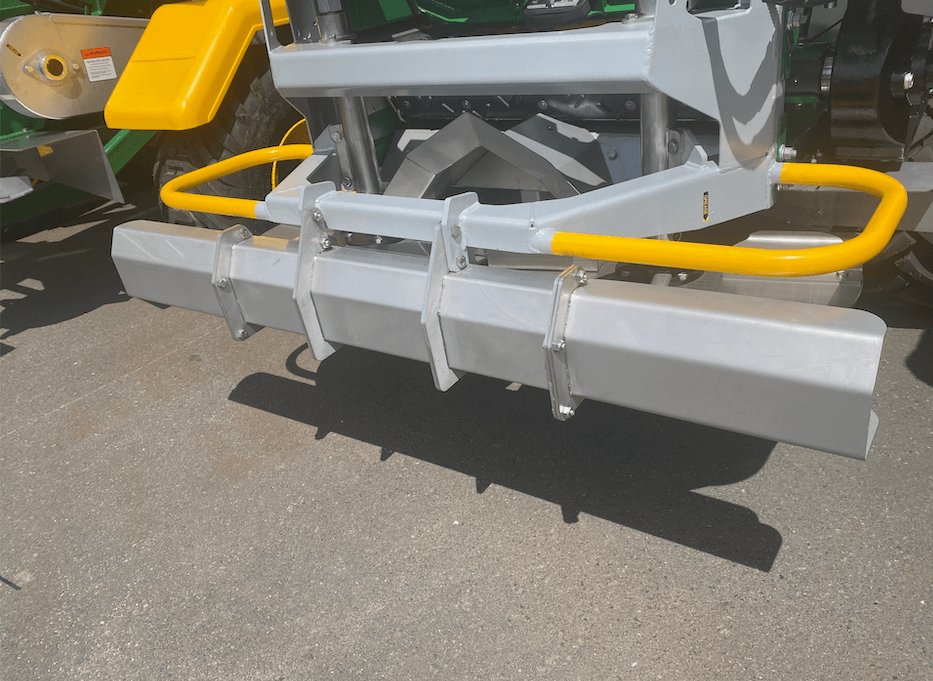

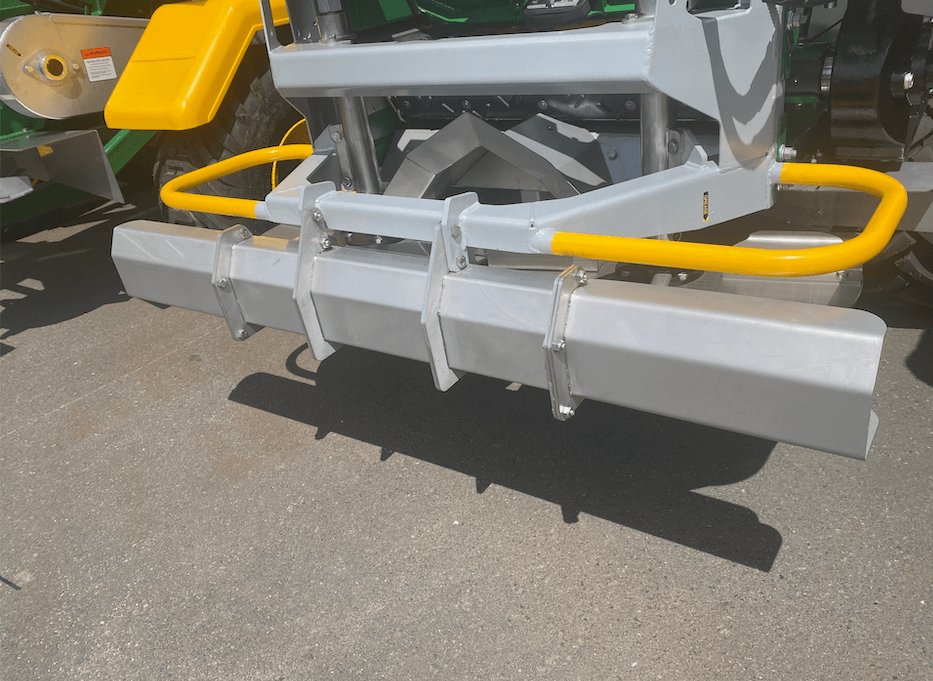

Centre banding modification

You can now centre band with every SAM Orchard Spreader! Excellent for spreading in a line in the middle of your machine or for piling in the centre. Superb for trench filling. It can even band rocks (with new optional bolt on protectors) as shown in this quick video.

-

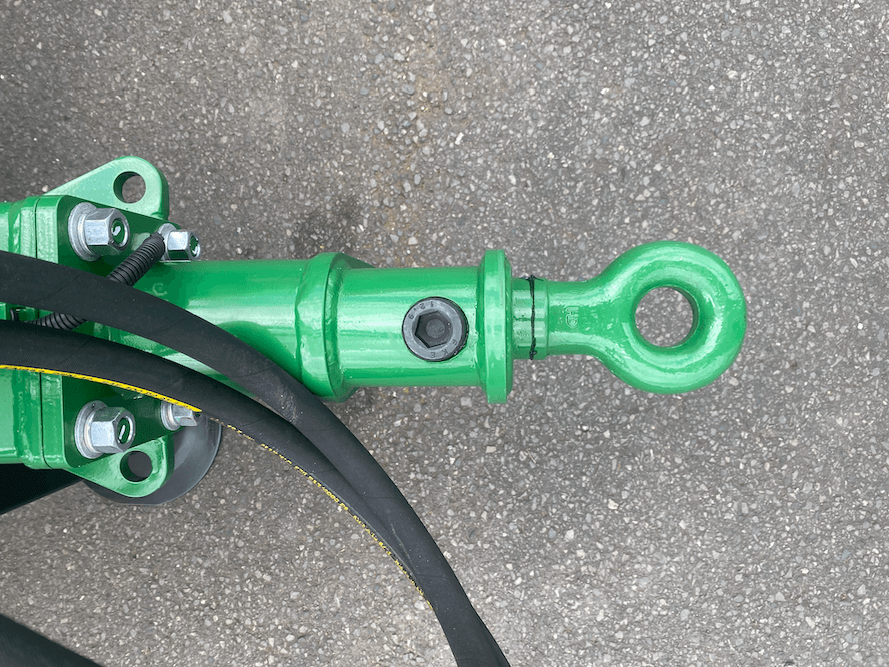

Swivel coupling

Orchard Spreaders come standard with a heavy-duty swivel coupling with an insert in the eye. This adds stability in varied terrain.

Optional Extras

- Standard cover

- LED lights

- Tyre variations

- Side attachment for spinners

- Centre blocker for spinners

- Tophat extensions

- Narrower bin

- Load cells & electric back door (Smart)

- Axle riser

- Left hand banding - rut filling

- Rut filler modification for rocks

- Safety chains

Standard cover

The standard cover is manually thrown across the load and fixed in place with bungys and stainless fasteners. Keeping it simple.

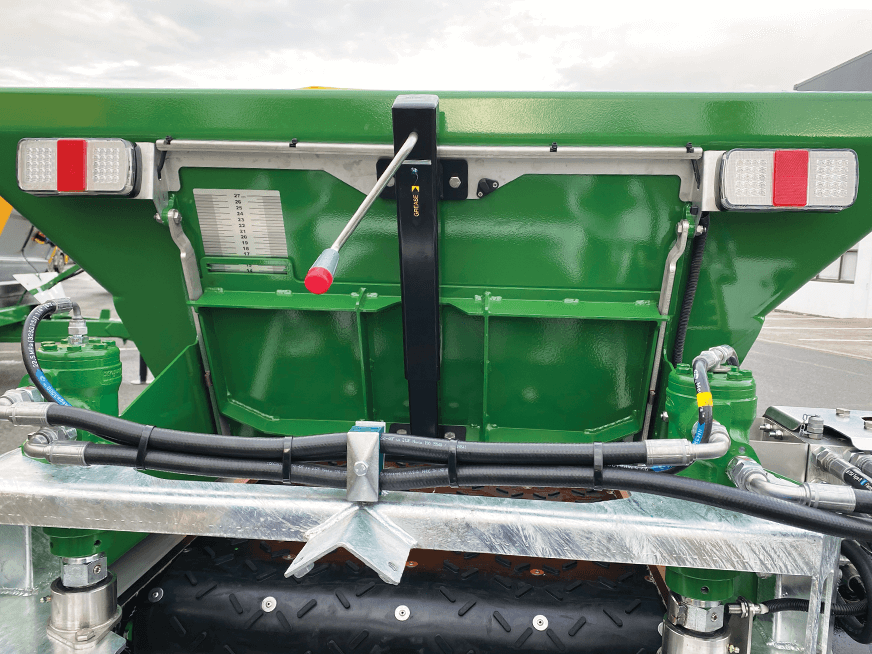

LED lights

If you are using your machine on the road you will need a set of lights. They are easy to mount and hardy for knocks and general wear and tear.

Weatherproof lights are LED and plug directly into your power source.

Tyre variations

We have tough high performing tyres to suit any application. They are chosen for their quality and durability.

We can change tyre sizes to suit your specific needs. 10/75 X 15.3 Tractor tread tyres are standard. Or you can go for a different tread.

Larger 400/60 X 15.5 12-ply tyres are also available. These larger tyres can be good if you have softer, wetter conditions. However they do add to the height of the machine.

Side attachment for spinners

Spreads to the right hand side of row only. It simply bolts on.

SAM simply switch the disc direction set up to suit.

Centre blocker for spinners

Centre blocker - spreads on the rows either side of your machine. It simply bolts on in the middle section.

You can also add bolt on wings to either side of the centre blocker. This is for blocking even more of the row.

The set up shown here has the centre blocker with the wings added.

SAM simply switch the disc direction set up to suit.

Tophat extensions

It is possible to increase the machines capacity by adding a tophat.

There are two sizes available. The largest top hat increases your capacity by 2 cubic metres (shown here). The smaller tophat increases your capacity by 1 cubic metre.

These have been popular for our New Zealand wine growers.

Narrower bin

Your machine can be manufactured with a narrower bin. Options are: 1.1, 1.3, 1.4 & 1.8m

Our 1.4m option has been very popular with hops growers.

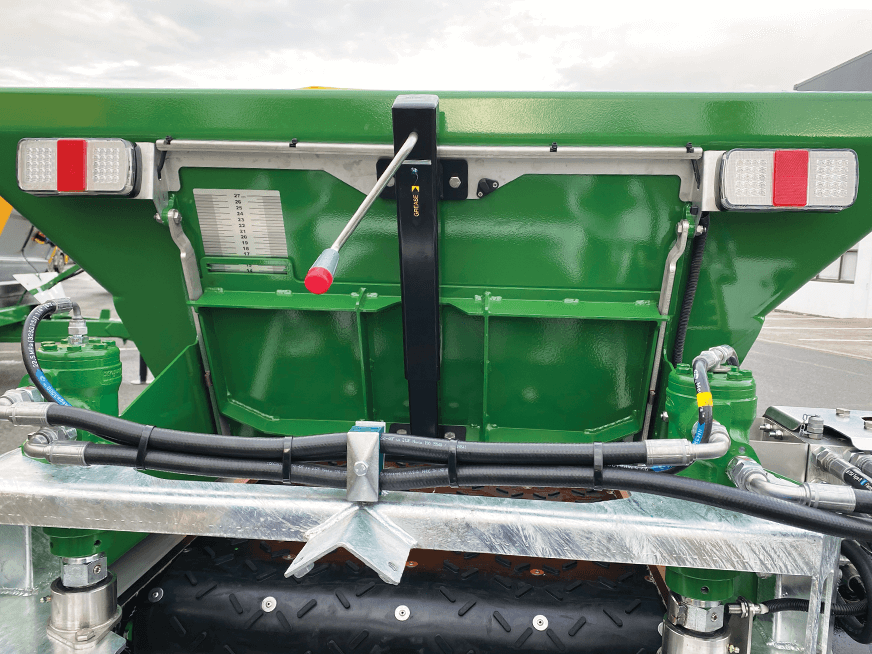

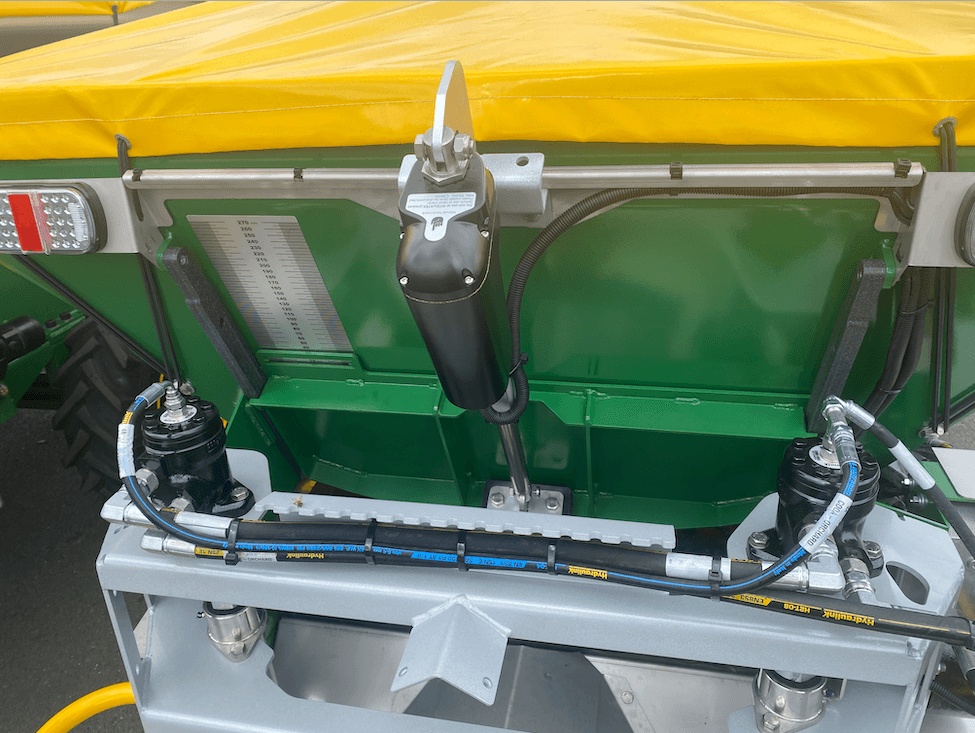

Load cells & electric back door (Smart)

Adding load cells give you improved accuracy as they are weighing the product in your bin. Orchard Spreaders have three load cells fitted.

All load cell machines now come standard with an electric back door which replaces the manual winding of the back door jack. The height is simply controlled from your screen.

Also handy for closing your back door when you are driving down the road so you are not losing any product out the back.

Axle riser

Some vineyard customers have requested to raise their axle by 150mm. You can do this by adding axle rises at the time of build. This set up is handy if you are on rocky or variable country where it is beneficial for your chassis and spreader discs to be sitting higher above ground.

Left hand banding - rut filling

We can enable your machine to also band/pile out the left hand side of your machine. This puts product directly in front of the left hand wheel. Great for filling ruts then compressing them with the weight of the wheel. POA.

Rut filler modification for rocks

These simply bolt on to protect the machine.

Safety chains

10mm safety chains can be added for towing peace of mind. 13mm also available.

Specifications

- Axle type Single-axle 70mm

- Axle capacity 6,000kg

- Wheel type 10/75 X 15.3 400/60 X 15.5 12-ply (upgrade)

- Jack type 70mm screw jack

- Overall length 4.75m

- Overall width 1.6m

- Overall height 1.44m

- Bin width 1.64m

- Bin length 2.94m

- Capacity 2.5m3

- Superphosphate 3.3T

- Lime 4.8T

- Urea 2.3T

- Tare Weight 1155kg

Fast central support service

Our SAM range is backed by a quick and efficient support service from central Hamilton. The team are also available for technical help should you need it.

Our guarantee

We deliver quality products and stand by them. All Spreaders go through rigorous quality and accuracy testing. They also have a comprehensive warranty.